thermal analysis

Making the invisible visible, detecting hidden problems that can cause critical failure

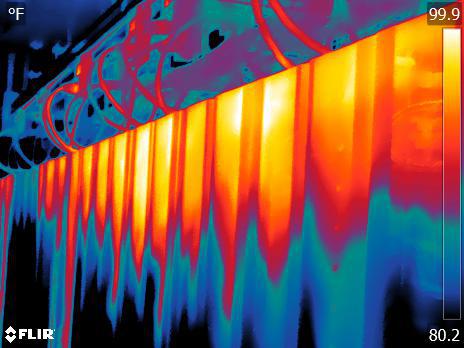

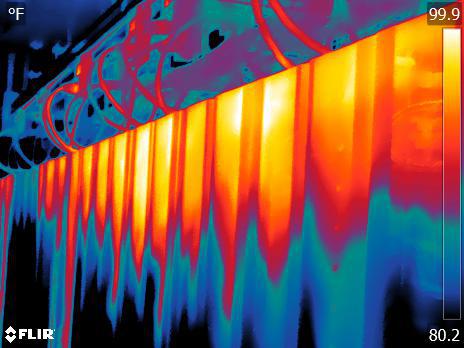

This picture depicts an improperly cooled data rack

Problems Encountered

This high profile data center, suffered from improper cooling of the racks leading to potential critical failures occurring.

Thanks to CST this was identified and fixed and not only did it lead to better efficiency but prolonged the life of the equipment.

Developing the Strategy

Performing a thermal analysis of a data center data floor includes collecting multiple data conditions within the floor area.

The strategy should focus on identifying and measuring the key variables that can impact the effectiveness of the thermal

management of the data center. In particular, the focus should be on the following:

We will inspect the installed perforated floor tiles, if applicable, by measuring the face velocity at the operational pressure to determine the

cfm flow rate. We will look for areas of low pressure induced by the velocity of the surface air (Bernoulli effect) usually found at the bottom

of the racks. We will check for low or no airflow at the top of the racks, or if hot isle air is migrating over the top of the racks to be used as

cooling air. We will measure the air flows to determine how the air is moving and how it is impacting the data center environment. We will also

assess the condition of the perforated floor tiles and determine if replacement is needed and if the existing grates are adequate for the system design.

Using thermal imaging cameras and specialized software, the temperature of components within the data center floor can be plotted on a graph.

This data can be used to compare various data points and identify possible hot spots or areas of high temperature.

In addition to thermography, other data points such as air velocity, air temperature, air pressure, and air flow direction can be monitored

and recorded with the help of sensors. This data can then be used to identify any potential hot spots or areas of high temperature.

Finally, the collected data can be compared to the set point of the cooling equipment, as well as the equipment performance and the desired

temperature of the data center. Any discrepancies between the data collected and the set point can be analyzed, and corrective measures can be

taken to ensure a proper thermal environment for the data center.

If further analysis is required, we can investigate the control system and review the trend logs to identify any variable load profiles that may

be affecting cooling. We can look for critical failure points and recommend mitigation strategies, such as hot/cold aisle containment strategies.

Our team is dedicated to providing the highest standard of quality assurance, using the most advanced techniques, technologies and

test equipment available. We conduct detailed surveys and inspections, analyze data and develop tailored solutions for each project, to

identify potential issues and create the most cost-effective and reliable mitigation plans. Our goal is to provide a clear understanding

of what is happening and put together an effective plan of action.

results

The implementation of these solutions has provided numerous benefits to businesses, including increased reliability and reduced operating costs,

increased ability to generate new customers, and reduced potential exposure to liability resulting from loss of services. Additionally,

businesses have seen improved customer service and satisfaction levels due to increased reliability and faster response times.

This has allowed businesses to expand their customer base and increase their revenues. Improved reliability also means that businesses

can operate with less downtime, making them more efficient and productive. Furthermore, this has enabled businesses to maintain their

reputation and attract more customers.